More Professional Consulting Services

The company has technical staff responsible for customer service at any time to provide you with product production process and use and technical advice.

More favorable prices

Price is not the most important factor in determining the purchase, reliable quality and high cost performance are the most important, and we will earn a little less than our peers, give customers more discounts, help customers reduce procurement costs, and expand more markets.

Humanized management of the company

We have been adhering to be an excellent person first, and then do a qualified business, to do business for a long time, and to treat customers as friends.

More powerful partners

With our strong strength, we can provide customers with confidence. With your support, we can develop better, and our progress will be beneficial to your business.

Our after-sales process

More effective communication allows our products and services to win more customers and improve efficiency for you.

- 2 hours to reply

- 24 hours to give the survey results

- 72 hours to give solutions

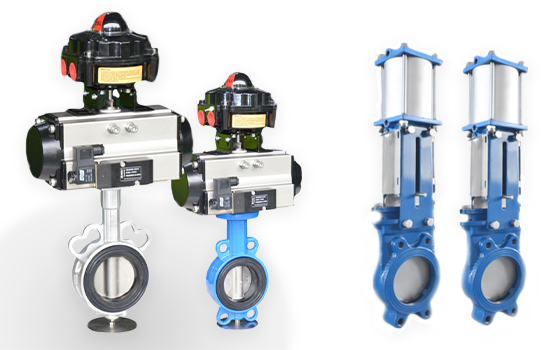

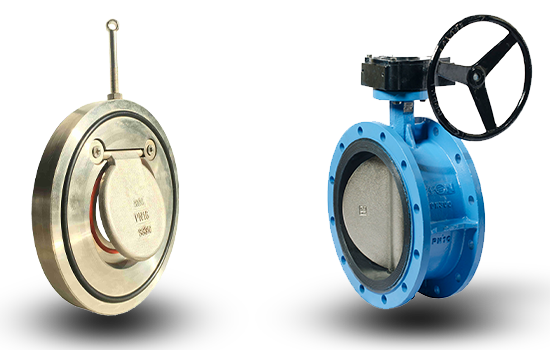

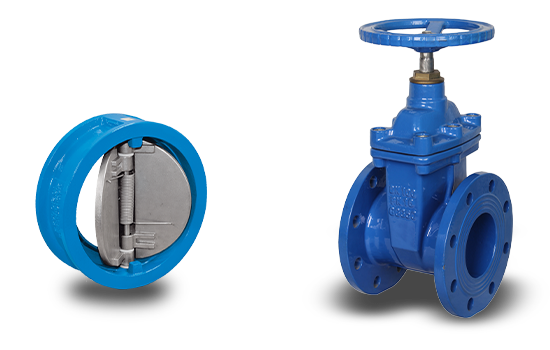

Valve Product Center

Professional valve manufacturer

ICV Valve is a valve factory established in 2007, covering an area of 21,000 square meters. It is a very professional valve manufacturer. It has a perfect one-stop professional production line such as foundry workshop, parts processing workshop, surface painting workshop, valve assembly workshop, etc. .

ICV valve products are used in sewage treatment plants, breweries, beverage plants, building water supply systems, air pipes, papermaking, glass, cold air systems, cooling water systems, heat exchanger water systems, ice storage air conditioning systems, fire water systems, high temperature Steam system, oil field pipeline system, pump base station, drainage system, natural gas pipeline....

Valve Professional Services

Delivery

10000pcs valve, we can deliver within 35 days

Certification

We can make relevant certifications for customers

Free samples

We can provide free samples to customers

Color customization

We can provide customers with various color customization

Any standard

We can produce any standard valve

Report

We can provide customers with: Certificate of Origin, 3.1 Material Report, Instructions for Use and Maintenance

Third-party inspection

We can pay for the third party inspection

Live Video

10000pcs valve, we can deliver within 35 days

Inventory

We can prepare inventory for customers to shorten the production cycle

Surplus 30%

We have always had a surplus of 30% of production capacity, in order to meet the urgent needs of customers for order production

Valve Application Scenarios

Knife gate valve application in water treatment plant

Butterfly valve application in sewage treatment plant

Butterfly valve used in vacuum air piping system

Gate valve used in water treatment pipeline

- What is a triple offset butterfly valve?A high performance butterfly valve. This valve has three offsets from the centre. The third offset is the elliptical seat geometry. This along with the two eccentric shaft offsets, allows the disc to seal against the seat with no friction. This seat design allows for uniform sealing, and thus bi-directional tightness at maximum differential pressure.

- Why use a triple offset butterfly valve?The triple offset design is used where bubble tight shut-off, zero leakage is required in common applications such as steam, chemical, refining, and offshore oil and gas. They offer a lower cost, lower torque option, than alternative style metal seated valves. It is low maintenance and offers an extended valve life.

- What is a double offset butterfly valve?A high performance butterfly valve. This valve has two stems offset from the centre. It is capable of providing accurate, stable, throttle flow control.

- What are PN10 and PN16?PN10 and PN16 specify metric flange measurements (such as bolt circle diameter, hole size, bolt size etc) according to such standards as ISO 7005-1 or DIN 2501. Our standard flanges are defined in the English system (inches) and most will not mate up with metric flanges. With Kennedy Valve's state of the art CNC machining capabilities our products can have flanges made to PN10 or PN16 specifications so that a connection can be made between our products and metric products (for example, one of our valves with a PN10 flange end can be attached to some metric pipe that also has a PN10 flanged end).

- What is the difference between Cast Iron and Ductile Iron?Ductile Iron is a newer stronger material, created by the addition of magnesium alloy to the molten iron. If a material can withstand extensive deformation without failing under high tensile stress, it is considered ductile.The result is an iron that is much stronger and harder to break, more corrosion resistant, and is easily machined.

- *Name

- *Tel

- *Title

- *Content

Become Our Partner (OEM&Distributor)

Meet various valve OEM and customization requirements, and provide cost-effective products and services.

Blog

- 135th Canton Fair Welcomes Buyers From All Over The World To Come To China To Find Partners135th Canton Fair Welcomes Buyers From All Over The World To Come To China To Find Partners

- Installation instructions for butterfly valve pipingInstallation instructions for butterfly valve piping

- 36 inch lug butterfly valve torque testOk Valve adopts advanced static torque testing instruments to create special torque testing instruments for 36 "butterfly valves.

- Function and principle of knife gate valveKnife gate valve has a shearing function to scrape off the sticky material on the seal face and remove debris automatically. The stainless steel gate prevents the seal from leaking due to corrosion. This article introduces the function and principle of knife gate valve.